About us

Committed to establishing long-term and stable cooperative relationships with global partners

Have

+

R&D personnel

Have

+

production line

Cover an area of

+

square meter

Have

+

R&D personnel

Have

+

production line

Cover an area of

+

square meter

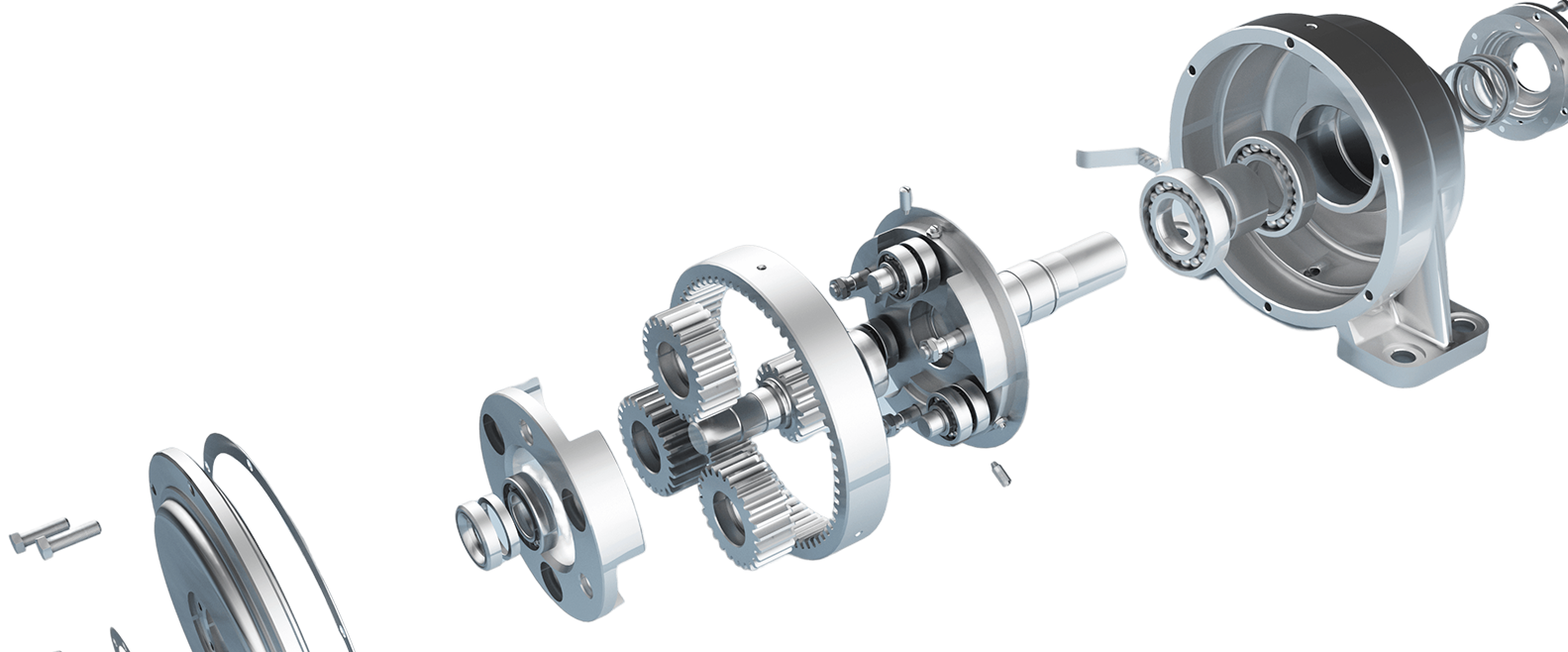

Committed to developing and promoting more environmentally friendly and efficient bearing products and technologies

•••

DUG Distributors can provide you with technical support and sales assistance。

Explore more50+

Country and Region

9000万

Annual output value

Regarding the explanation of bearing solutions, if there are more specific issues or a need for more in-depth solutions,

Suggest directlyContact UsSeeking Consultation。

From product development to pre-sales, sales, and after-sales service, every link truly puts customer needs at the center,

Adhere to the route of putting customers first, providing quality services, and continuously striving for excellence.

Do as you please, satisfy everything

Nationwide, worry free service

Transportation is controllable and the product is undamaged

Ultra long warranty, worry free quality

Efficient, convenient, and unobstructed

Faced with the challenge of global climate change,...

Learn moreWith the rapid development of industrial automatio...

Learn moreWith the continuous development of the field of oc...

Learn moreRecently, at an international trade exhibition, th...

Learn moreCan't find the information you're looking for? Please fill out the application form and we will reply to you as soon as possible

Your local DUG dealer can provide you with technical support and sales assistance.

DUG online customer service, timely answer customer questions

(Monday to Friday 9:00-18:00)