There are various types of aircraft bearings. In response to customers' demands for reducing weight, environmental pollution, and high performance of bearings, bearing systems have become more complex and require higher reliability and quality control. Design theory and industry development trend of main shaft bearings for jet engines. With the rapid development of emerging markets and the global expansion of low-cost airlines, the demand and sales of commercial aircraft have steadily increased.

The model aircraft engine first only has two high-temperature ceramic ball bearings, and the market price is generally around 300. Secondly, the combustion chamber is too rudimentary, with low combustion efficiency and high fuel consumption. The turbine blades do not have cooling devices or a complete lubrication and cooling system, and the structure is too simple.

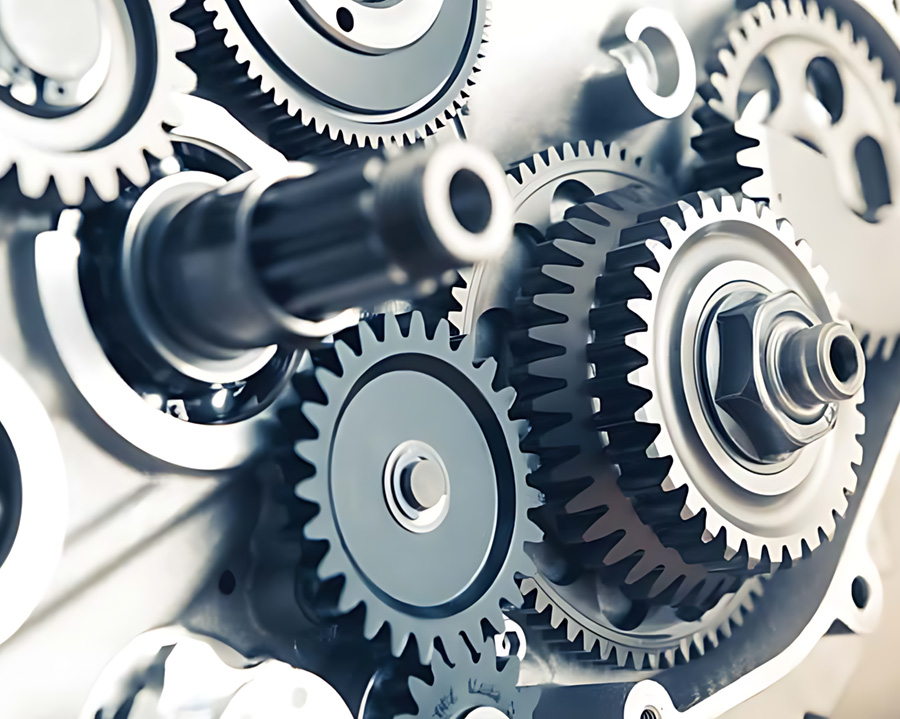

High speed turbine engines generally use fully floating bearings to reduce friction, which can only transmit torque and reduce friction to a low value. Angular contact ball bearings are only used to withstand other torques, and axial thrust is mainly borne by thrust bearings.

The engine blades are mainly composed of composite materials, and there are not many requirements for compressor blades. There are lubrication tracks and air passages in the engine shaft.

There is an air duct between the turbine blade and the guide vane, and small holes are made on the surface of the blade by laser. During operation, a gas film is formed on the surface of the blade to separate high-temperature gas.