Powder metallurgy bearings are made by pressing, sintering, shaping, and immersing metal powders and other anti friction material powders in oil. They have a porous structure, and after being immersed in hot oil, the pores are filled with lubricating oil. During operation, due to the suction effect and frictional heating caused by the rotation of the journal, the metal and oil are heated and expanded, pushing the oil out of the pores and lubricating the friction surface. After the bearing cools down, the oil is sucked back into the pores.

Powder metallurgy oil containing bearings (oil containing bearings) are a type of porous alloy product with lubricating oil immersed in the pores. When the shaft rotates, the friction between the shaft and the oil bearing causes the temperature of the oil bearing to rise and the pumping effect to occur. Lubricating oil infiltrates from the friction surface of the inner or outer diameter of the oil containing bearing when the shaft stops rotating. The lubricating oil flows back into the oil containing bearing. Therefore, the consumption of lubricating oil is very small and can be used for long-term operation without external supply of lubricating oil. Very suitable for situations where oil supply is difficult and lubricating oil pollution is avoided.

Oil containing bearings are widely used in various mechanical equipment such as the motor industry, automotive and motorcycle industry, home appliance industry, digital products, office equipment, power tools, textile machinery, packaging machinery, etc.

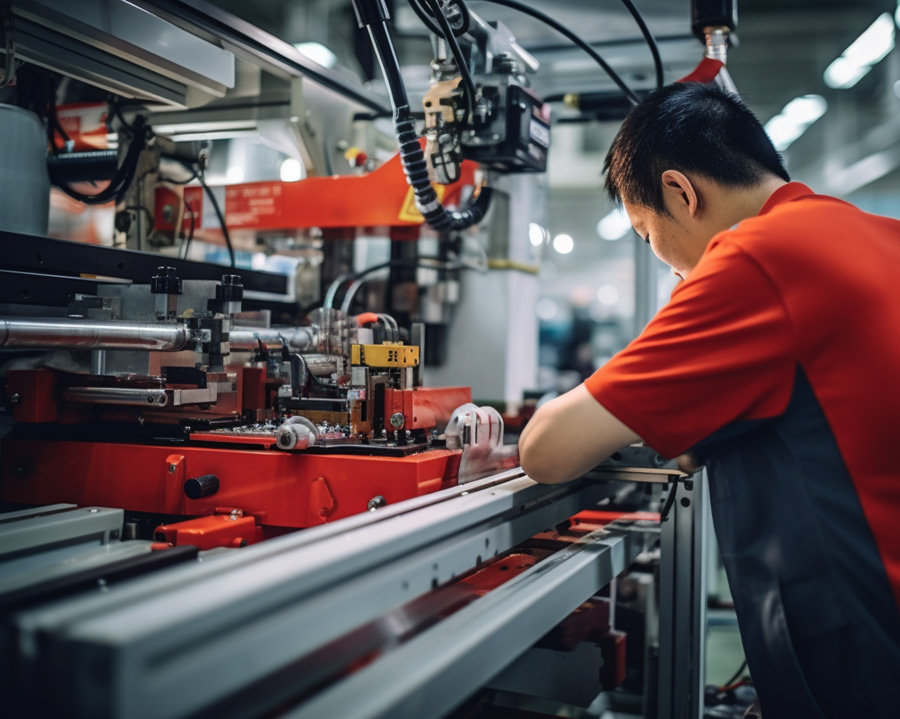

Powder metallurgy oil containing bearings are generally manufactured using raw material powder through processes such as pressing, sintering, shaping, and oil immersion. Most machines nowadays have a relatively high degree of automation. The daily production is relatively large, and most products can be formed in one go, so the larger the batch, the better the production. And if we use fewer molds now, we may make hundreds of thousands of them, and if we use more, we may make millions or more. But the cost of molds is relatively high, so it is difficult to produce in small batches, and the time to replace molds is also long.

Generally speaking, powder metallurgy oil containing bearings can be formed in one go without the need for cutting. The cost is lighter than machining and there is less material waste, so the price is relatively cheaper. It also conforms to the national policy of advocating energy conservation, so it is considered a technology that will not fall behind.