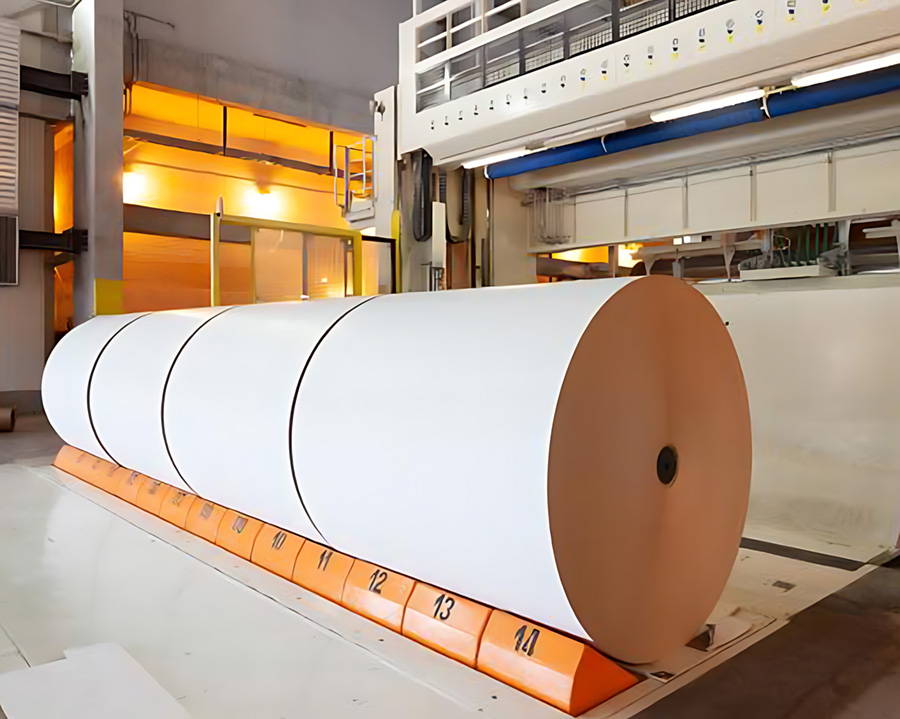

Pulp and paper bearings

Meeting the needs of a challenging industry

Market forces and increasingly stringent regulatory requirements have made it more difficult than ever for pulp, paper, and paper processing operations to be profitable. The competition is fierce and increasingly globalized. The costs of energy and raw materials remain high and are increasingly rising, as are the costs associated with new health, safety, and environmental legislation.

Paper mills are facing unprecedented pressure and have to focus on process efficiency, machine reliability, and all other factors that affect factory production efficiency and profitability, from training to various information technology factors.

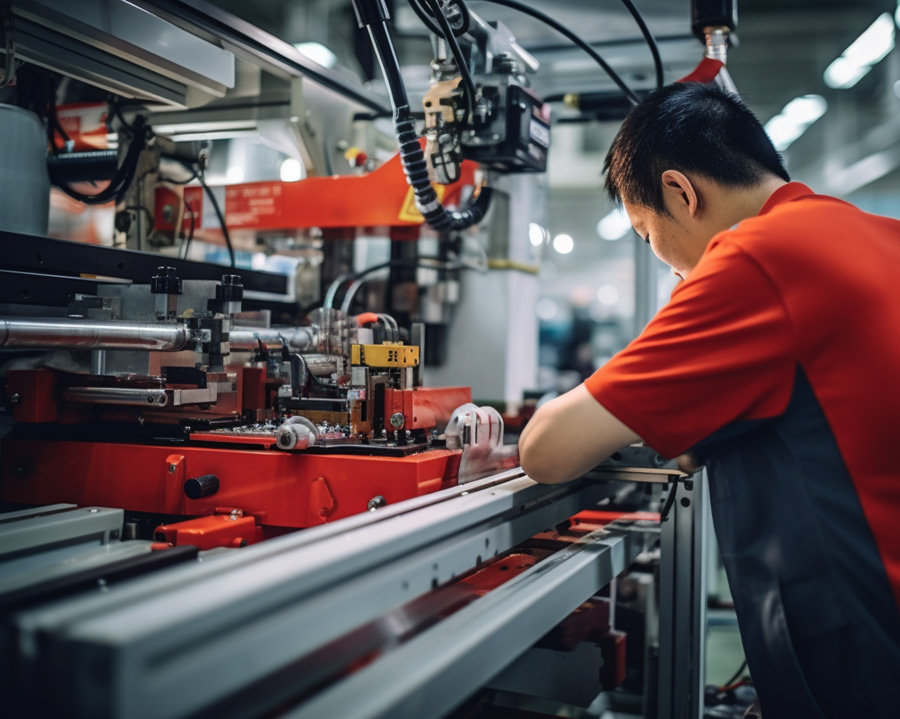

Pulp and paper solutions provide improved production efficiency and profitability. By combining expertise in bearings, seals, lubrication, mechanical electronics, and services with years of rich experience in pulp and paper solutions, we provide a range of solutions for paper mills to promote production and reduce maintenance needs.

The solutions provided cover all aspects from professional bearings and seals to condition monitoring technology, maintenance tools, expert consultation, and bundled reliability services, which help:

Increase production

Reduce downtime

Reduce maintenance costs

Reduce energy consumption and consumables loss

Improve worker safety

Upgrade or optimize equipment

Minimize capital expenditures to the greatest extent possible